ISO2531 En545 En598 Class K7 K8 K9 C25 C30 C40 Water Pressure Ductile Iron Pipe Casting Pipe

Basic Info.

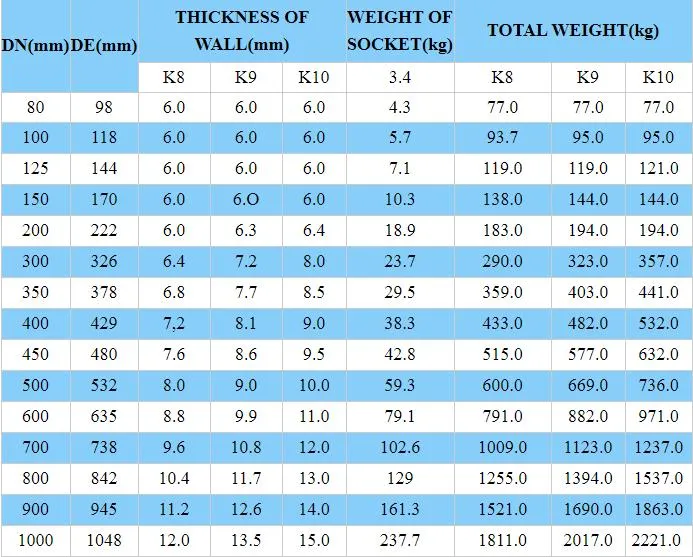

| Model NO. | ISO2531 En545 En598 Class K7 K8 K9 C25 C30 C40 |

| Certification | ISO2531, EN545, EN598 |

| Shape | Round |

| Customized | Customized |

| Color | Black,Red, Blue or as Request. |

| Specifications | DN80mm-2600mm |

| Hardness | 230hb |

| Tensile Strength | >420/MPa |

| Price Term | 30%Tt for Deposit, 70% Balance Before Shipment |

| Application | Drinking Water Sewage Water |

| Standard | ISO 2531, En545, En598 and Other Major Standards. |

| Processing Service | Welding, Bending, Cutting |

| Class | K9 .K8 K7 C40 C30 |

| Model No | DN500 DN800 DN1000 DN1200 |

| Length | 6m or Customized |

| Keywords | Ductile Iron Pipe |

| MOQ | 5tons |

| Delivery | 7-15 Days |

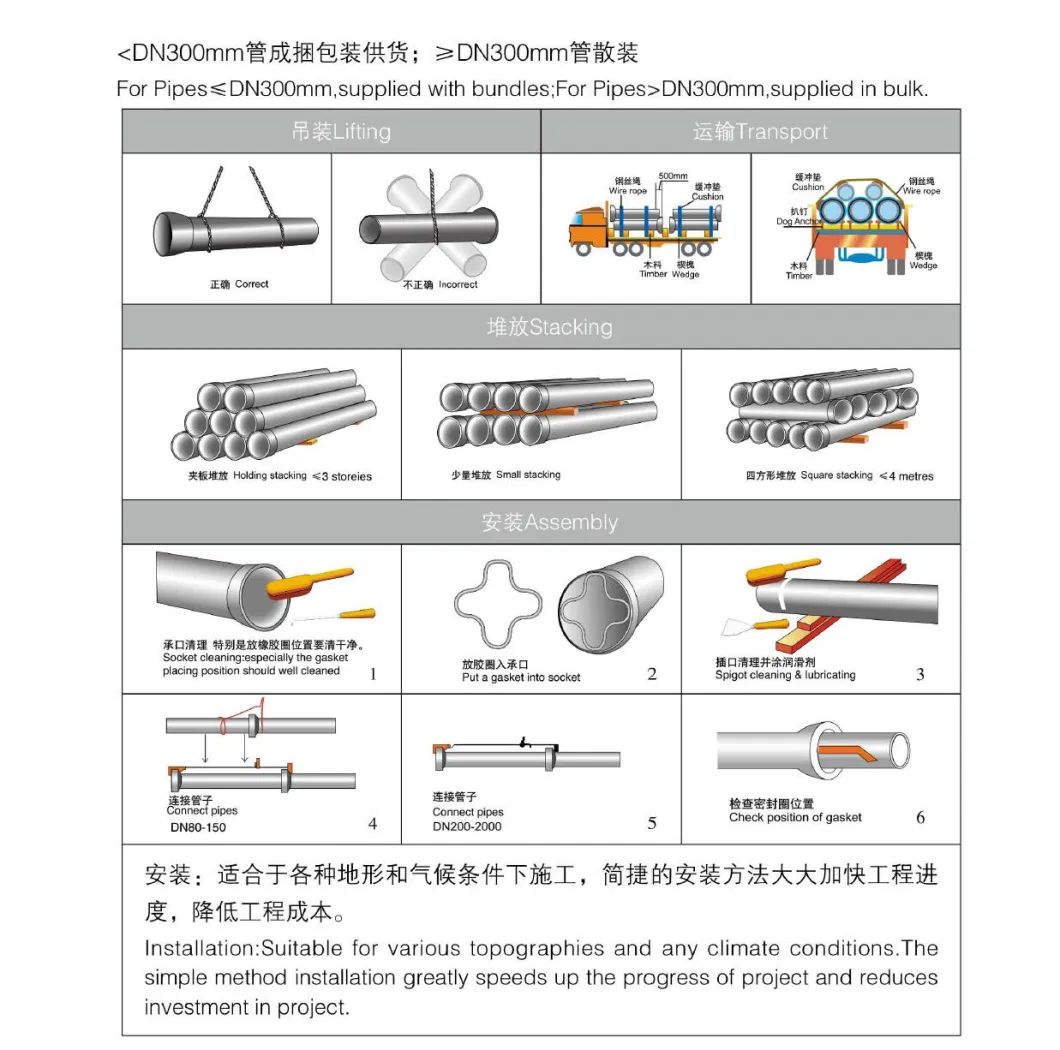

| Transport Package | Bundled with Steel Belts or in Bulk |

| Specification | DN80-DN2600mm |

| Trademark | TATA |

| Origin | China |

| Production Capacity | 5000ton/Monthly |

Product Description

| Product Name | Ductile Iron Pipe |

| Pipe Class | K9, K8, C40, C30, C25, etc. |

| Diameter | DN80-DN2600 mm |

| Length | 6m, cut to 5.7m.In general, the pipe length is 6m for bulk shipment and 5.7m for container shipment. |

| Pipe Joint | T type push-on joint, K type joint, self-restrained joint |

| Lining and Coating | Internal Lining: cement mortar lining as per ISO 4179 |

| Zinc Coating:at least 130g/m2 as per ISO 8179 | |

| Bitumen Painting : at least 70um as per ISO8179 | |

| Pressure | PN10, PN16, PN25,PN40 |

| Features | High strength, lighter than gray iron, good corrosion resistance, no furring, small flow resistance, easy fixing, long life |

| Application | Water supply project, drainage, sewage, irrigation, water pipeline. |

| Packing | Bundled with steel belts or in bulk |

Metallic zinc coatingWhen metallic zinc spray is applied, the mean mass of the zinc per unit area shall be not less than 130g/m2 , with a local minimum of 110 g/m2. The mass of the zinc according to customer's request is also available.Bitumen coatingThe mean thickness of bitumen coating shall be not less than 70 μm and local minimum thickness shall be not less than 50 μm. The thickness of bitumen coating according to the customer's request is also available.Alternative coating

| External coatings | Internal coating(linings) | Coating of the joint area |

| - Metallic zinc with finishing layer, in accordance with ISO 8179-1;- Zinc rich paint with finishing layer, in accordance with ISO 8179-2;- Epoxy coating, in accordance with EN 14901;- Polyethylene sleeve, in accordance with ISO 8180;- Alloy of zinc and aluminum with or without other metals, having a minimum mass of 400 g/m2, with finishing layer;- Extruded polyethylene coating in accordance with EN 14628;- Polyurethane coating in accordance with EN 15189;- Cement mortar coating in accordance with EN 15542;- Adhesive tape; | - Portland/Blast furnace slag/Sulphate/ High Aluminum Cement Mortar, in accordance with ISO 4179;- Cement mortar lining with seal coat, in accordance with ISO 16132;- Epoxy coating, in accordance with EN 14901;- Polyurethane lining in accordance with EN 15655; | - Epoxy coating;- Polyurethane coating |

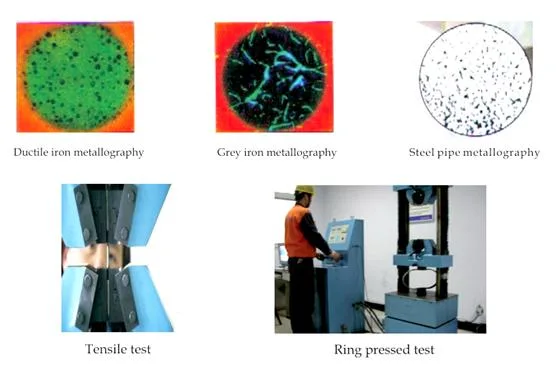

Process and testing:

1. Induction furnace and treated metal (Chemical analysis of raw material, spheroidizing & Nodularity)2. Casting (Visual check and weight check)3. Heat treatment (Micro structure)4. Hydrostatic test (Pressure test)5. Dimensional checks (Checking pipe length and joint, OD, wall thickness, appearance)6. Zinc spraying (Thickness testing)7. Lining and coating (100% visual check, thickness testing randomly)8. Marking and packing (100% visual check)

Project Case

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur. Q5: How many countries you already exported to?

A:We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana,somalia and other African countries.Our export experience is rich, we familiar with different market demands, can help customers avoid a lot of trouble.Q6.Do you provide custom made Products service?

A: Yes,if you have your own design , we can produce according to your specification and drawin